Discover our parts and components for conveyor and sieve webs – suitable for every agricultural application. Questions? Feel free to contact us at sales@broekema.nl.

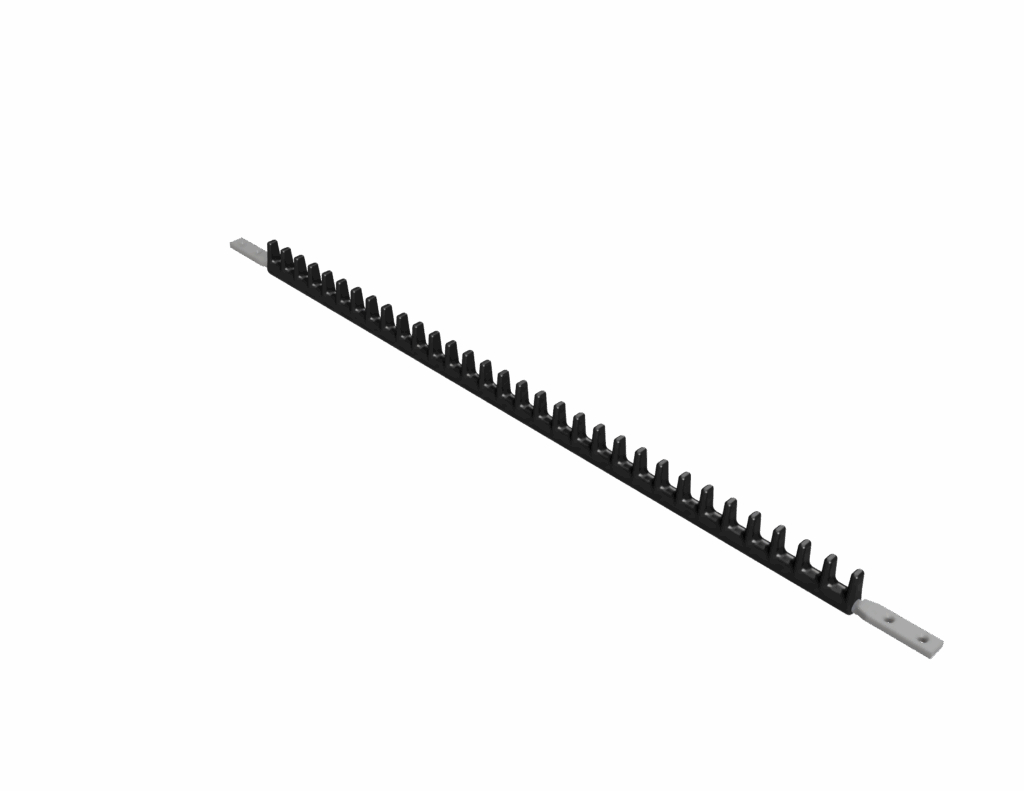

Home / Products / Rods / Pintle bars / 1-row pintle

The 1-row pintle is designed for lighter-duty applications or where more open spacing is needed. With only one row of pintle fingers, it offers selective cleaning while minimizing contact with sensitive crops. Often used in crops where minimal bruising and gentle handling are priorities.

| Web width | Belt width | CTC | Rod Ø | Rivet Ø | Number of belts |

|---|---|---|---|---|---|

| 300 | 50 | 20 | 10 | 5 | 2 |

| 350 | 50 | 24 | 10 | 5 | 2 |

| 750 | 50 | 24 | 10 | 5 | 2 |

| 900 | 50 | 20 | 10 | 5 | 2 |

| 1000 | 50 | 20 | 10 | 5 | 2 |

| 1103 | 50 | 24 | 8 | 5 | 2 |

Best suited for gentle handling and basic cleaning requirements.

Pintle belts are primarily used for additional cleaning—during harvest or post-processing. Rubber pintle fingers remove haulm and allow products like carrots or potatoes to roll back into the process.

Each pintle web is built using pintle bars, which come in various types and materials. While the structure affects cleaning performance and durability, other factors like mounting type and bar pitch are also critical. Pintle bars can be riveted or clipped and may include support from a center traction belt to prevent sagging—especially in wider webs or with flat strip-mounted pintles.

Two popular connection methods for pintle belts are the BSV clip (where rods are riveted on the clip) and the Lap joint (e.g. 2-2-2). In the latter, the user must install the 6 loose pintle bars themselves to close the belt. The spacing and pitch of each bar determine both sieving performance and product retention.

Resources

©2024 EA Broekema BV