Home / Company / Case studies / Street Sweepers with Broekema Belted Chain

Efficient street cleaning is crucial for urban cleanliness and maintenance. Traditional street sweepers can face frequent maintenance issues and inefficiencies, causing increased operational costs and downtime. The integration of Broekema belted chain technology in street sweepers offers a solution that enhances efficiency, reduces maintenance needs, and ensures a long operational lifespan. This case study examines the deployment of Broekema belted chain systems in street sweepers.

The challenges faced included frequent breakdowns and maintenance issues with traditional conveyor belts, high noise levels during operation, rapid wear and tear, and high operational costs due to frequent repairs and downtime. The objective was to implement Broekema belted chain technology in the dirt conveyance system of street sweepers to reduce maintenance costs, ensure consistent and quiet operation, minimize downtime, and extend the overall lifespan of the equipment.

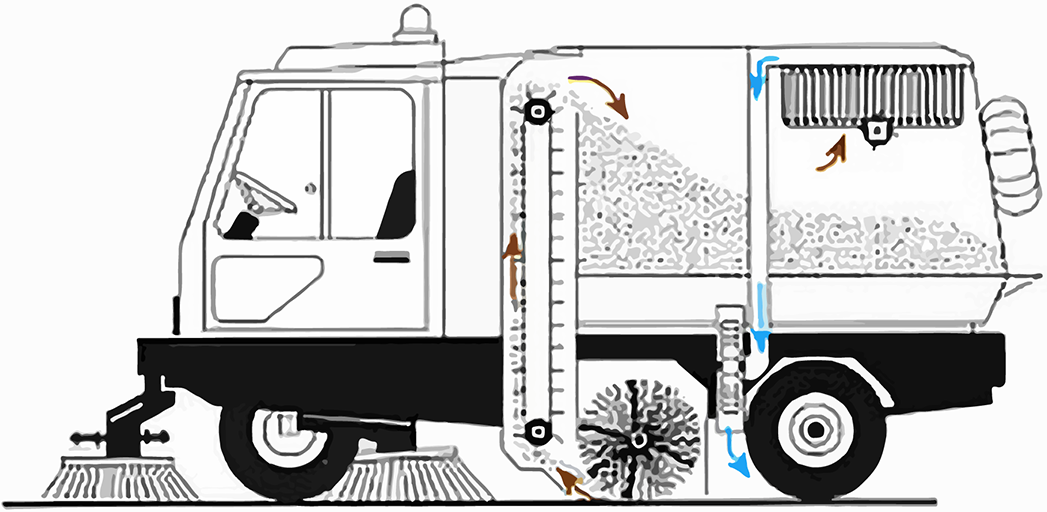

The solution involved equipping street sweepers with Broekema belted chain systems designed to be robust, low noise, low maintenance, and low wear with a long lifetime. The durable belted chains ensured reliable and efficient transportation of dirt and debris from the pickup point to the collection bin. The robust design minimized wear and tear, while the low-noise operation reduced noise pollution during street cleaning. The low maintenance requirements and long operational lifespan of the Broekema belts significantly reduced downtime and operational costs, improving the overall efficiency and effectiveness of the street sweeping operations.

Want to discuss your conveyor belt needs?