Ontdek onze onderdelen en componenten voor transport- en zeefbanden – geschikt voor elke agrarische toepassing. Vragen? Neem gerust contact op via sales@broekema.nl.

The EN0300 Hydro FG traction belt is specially developed for humid or washdown environments, where fabric longevity is critical. Made with closed blue rubber sidewalls, it prevents moisture from penetrating the fabric, significantly improving the lifespan of the belt. This makes it highly suitable for applications in food processing or other wet conditions. The EN0300 FG features a low cam profile (3 mm), allowing flexibility while offering protection against return rollers. With its narrower 50 mm fabric inside a 60 mm belt, this version has slightly reduced tensile strength but gains in hygiene and moisture resistance.

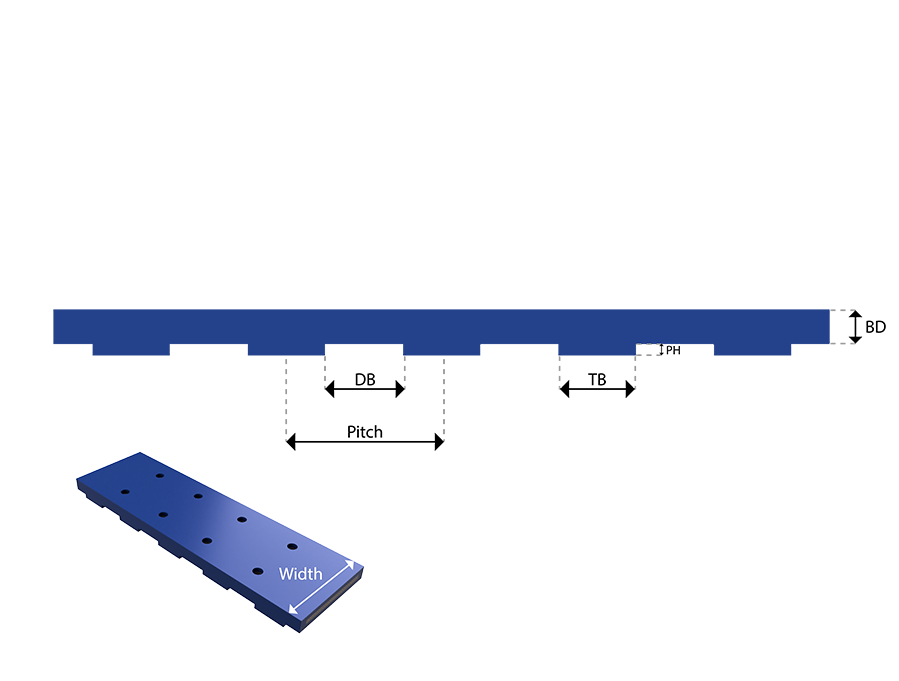

| Pitch | Width | Strength | TB | DB | PH | BD |

|---|---|---|---|---|---|---|

| 28 | 60 | 800 | 7,9 | |||

| 28 | 60 | 1000 | 7,9 |

| Extra info | TN900 | TN1000 | TN1200 |

|---|---|---|---|

| Strength per cm | - | - | - |

| recommended pretension (in %) | - | - | - |

| Elongation at break | - | - | - |

| Rubber ShoreA | - | - | - |

| Pitch tolerance | - | - | - |

| Belting width tolerance | - | - | - |

| Wear resistant (DIN 53516) | - | - | - |

| Moisture absorption | - | - | - |

Moisture-resistant belt with food-grade properties for wet applications.

At Broekema, we meticulously engineer our traction belts to ensure slip-free power transmission in agricultural and other demanding applications. Each belt is made from advanced rubber compounds formulated in-house within the Jäger Group, guaranteeing excellent wear resistance and a secure bond with the internal fabric layers. By using specialized fabric constructions, including pre-stretched warp threads, we reduce unwanted elongation so the belt’s cam pitch remains accurate over time.

We offer a range of fabric strengths, from TN900/3 (ideal for most general uses) and TN1000/2 (enhanced flexibility) to TN1200/3 (heavy duty). Choosing the right option involves striking a balance between tensile strength and maneuverability. For instance, while heavy-duty belts can handle substantial loads, they may be less flexible for tight corners or smaller roller diameters; on the other hand, a belt that’s too light might struggle under continuous heavy loads.

Another factor in maintaining belt longevity is the slight under-tolerance applied to the pitch during production. This allows installers to tension the belt precisely, aligning the cams correctly with the sprockets and minimizing premature wear. In practice, this means a more stable operation, fewer risks of slippage, and reduced downtime for maintenance or repairs.

Ultimately, choosing the right Broekema traction belt comes down to understanding your application’s specific needs—load requirements, environmental conditions, and the degree of bending in your setup. By matching the belt to these factors, you can achieve reliable performance, maximize service life, and keep your operation running smoothly.

Direct naar

Middelen

Ons bedrijf

©2024 EA Broekema BV